Global Sustainability and the Impact of Pharmaceutical Temperature Controlled Packaging

Key Takeaways:

– The healthcare industry is one of the largest single contributors to global warming

– Along with many others, the pharmaceutical industry is being pushed to become more sustainable

– Some things – like air transit – aren’t controllable, but packaging certainly is

– Disposable packaging presents a number of issues in the march to global sustainability in the pharmaceutical industry

– Not only is reusable packaging more sustainable, but it also reduces the risk of destroyed or ineffective product through precise temperature control

– Pharmaceutical temperature monitoring is vital throughout the end-to-end cold chain, and the right packaging provides verifying data and improved visibility

Insulated reusable packaging can help you meet your sustainability goals

There’s a push in all industries to reduce their environmental impact. Increasing pressure is being felt by the pharmaceutical cold chain, creating new challenges for a sector that already faces strict safety standards. Pharmaceutical companies have joined others pledging to reach Net Zero by 2050 to meet the United Nations goal, and are focused on reducing carbon emissions in the entire value chain. It’s a complex issue that requires attack from many angles.

The challenge? Balancing logistical demands and environmental impact. Transportation has a huge impact, but shipping drugs by air is vital and many products require careful handling. Keeping these shipments at the required low temperature within a limited time window means air transport is essential for temperature control. Planes pollute, and there’s already intense pressure to reduce healthcare’s substantial carbon footprint.

While it’s not currently possible to choose a plane that pollutes less, it is possible to choose more environmentally sound packaging to reduce impact. Currently, most pharmaceuticals are shipped in an unsustainable way, packed into single-use insulated cardboard boxes with a coolant.

The solution? Reusable packaging that also provides reliable temperature control. This march to environmental sustainability will take a collaborative effort between the pharmaceutical industry and their packaging vendors.

Emissions and the medical cold chain

Temperature can affect the stability of many compounds, and high temperatures can destroy or reduce their effectiveness. Blood samples and vaccines are both thermosensitive biological products that can degrade if exposed to sub-optimal temperatures, rendering them useless. It’s therefore critical to ensure that products that require stable temperatures are protected from extreme variations, safely stored, and properly transported across the entire supply chain.

Enter the medical cold chain, consisting of medical-grade freezers and refrigerators coupled with transportation solutions crafted to maintain the ideal temperature for biological materials as they move through the chain.

The issue? These solutions not only consume incredible amounts of energy, but they also pose a substantial risk of environmental damage if they use the chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) refrigerants that were so common in past decades. These refrigerants cause severe damage to the ozone layer and contribute to global warming. Although a switch has been made to more sustainable refrigerants, many of the older models are still in use.

The environmental cost doesn’t just come from polluting transport options and refrigerant emissions. Disposing and replacement of degraded or spoiled pharmaceuticals dramatically increases carbon emissions as well, because incineration is the method of choice for the destruction of drugs. But perhaps the biggest change pharmaceutical cold chain leaders can take to improve sustainability is to make the switch from single-use to reusable packaging.

The role of disposable vs. reusable packaging in sustainability

Temperature control during transit is required for vaccines and insulin, as well as for drugs made from living organisms (biologics), such as those for cancer and rheumatoid arthritis. The sales of these types of drugs continue to increase. More pharmaceuticals in the cold chain present more emissions, which makes sustainable packaging options that provide precise pharmaceutical temperature monitoring a key component of sustainability initiatives in shipping.

The problem with disposable packaging

Disposable packaging is typically a single-use box packaged with a coolant such as a gel pack or dry ice. While the simple cardboard box has the lowest cost, it also has the lowest temperature accuracy.

And then there’s the waste management of this type of packaging. The coolant materials may be able to be reused, but the actual packaging is disposed of, often by burning, which releases pollutants into the air.

Companies using disposable containers are finding it harder and harder to justify their place in a world focused on sustainability. Even when these solutions incorporate compostable materials, it’s unclear whether they strictly follow their end-of-life plan, and verification is difficult. Plastic packaging presents an even larger problem when it comes to disposal.

The drive for sustainability has pharmaceutical companies looking for packaging partners with a sustainability mindset and the products required to increase sustainability. A reusable packaging system can both control temperature and provide pharmaceutical temperature monitoring. Let’s take a look at the benefits.

The advantages of reusable packaging go beyond temperature control

The stakes are high, and not just for the environment. If not kept at the proper temperature, millions of dollars can be lost in just one package, and the biopharma industry loses about $35 billion each year because of logistical failures in temperature control.

When it comes to pharmaceutical shipping, precise temperature control is essential. And with many pharmaceutical manufacturers expanding into global markets, product protection comes even more into focus. One looming issue is maintaining temperature when shipping to underdeveloped regions that have no cold chain infrastructure. Reusable packaging is up to this challenge.

These packaging systems depend on technology to keep a consistent temperature. In addition, reusable packaging:

- Can successfully endure both long periods of travel and ambient temperature extremes

- Can be used as a refrigerator to maintain the ideal temperature

- Reusable boxes mean they’re more cost-effective

- Reduces requirement for refrigeration, including dry ice

- Maintains temperature stability comparable to active refrigeration

- Can be used for active or passive temperature control

The list of problems that can be encountered when shipping life science products globally is long, including weather delays, aircraft mechanical issues, and extreme temperature fluctuations. Active packaging conquers issues where disposable packaging fails.

Temperature confidence

An insulated, reusable dry ice shipping box coupled with integrated temperature loggers means you can have confidence that the proper temperature has been maintained at all times while in transit or in the warehouse. Your products are protected end-to-end in the cold chain.

Data means increased visibility

These reusable packaging systems provide temperature performance tracking via data logging that can be analyzed at the end of the shipment. This enhanced visibility into the cold chain means that not only are you able to make better cold chain management decisions, but you have the necessary documentation showing that all regulations are being followed.

Better packaging means less risk

Your cold chain must be protected from origination to the end user. The right packaging offers more efficient insulation than disposable boxes, is more cost-effective, and maintains temperature stability over and above even active packaging solutions.

By collaborating with the proper packaging provider, pharmaceutical companies can make huge strides in their global sustainability initiatives, reducing the cost to the planet while also reducing financial losses.

The environmental pillar of any pharmaceutical sustainability initiative is heavily influenced by its supply chain, which is the largest percentage of the industry’s carbon footprint. Choose your packaging wisely.

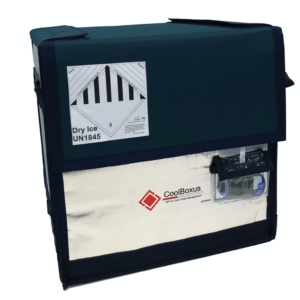

CoolBoxus is the answer for globally sustainable packaging

At Marathon Products, we’re dedicated to sustainability. Our CoolBoxus validated shipping boxes ensure your cold chain is complete from end to end. In transit or in the warehouse, our reusable CoolBoxus solution means total protection no matter where your product is in the cold chain.

The VIP (vacuum insulation panel) technology contained in CoolBoxus solves temperature-related problems for our pharmaceutical partners and improves cold chain operations. The insulating material used within the walls of our boxes is 10 times more efficient than traditional insulation.

This means maximizing space while minimizing weight and size to achieve a more stable temperature range when compared to active cooling solutions, which turn on and off at threshold temperatures. Integrated temperature loggers add assurance that your shipment was always at the right temperature.

Learn more about how CoolBoxus can help power your sustainability initiatives. Marathon Products helps you stay connected to your shipments and our service is second to none. Give us a call at 800-858-6872 or send us an email at web-inquiry@marathonproducts.com and we’ll get back to you right away.