Next Generation Quality Control in the IVF Laboratory Using data loggers to monitor real time incubator temperature

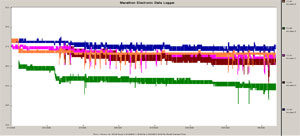

Quality Control (QC) in the IVF laboratory plays an important role in the success of any IVF program. The role of QC procedures in the IVF laboratory is to fine tune existing protocols in order to more effectively help infertile patients in their quest to have a healthy baby. The three most important physical conditions in the IVF laboratory that can be controlled are temperature, pH and osmolality. Laboratories are required to document and monitor these physical conditions regularly as part of their ongoing QC/QA programs. Monitoring and documentation of temperatures inside incubators, refrigerators and freezers is an integral part of routine day to day QC in the IVF laboratory and is a prerequisite for accreditation by CAP, JCAHO or other agencies. In laboratories with multiple banks of incubators and freezers this is a time consuming and laborious process. In large volume laboratories this process can take up to 1 hour every day. Here, we find a new application for real time temperature logging by introducing this system into the IVF laboratory. Data loggers continuously transmit temperature of incubator, freezer and refrigerator interiors at set programmed intervals directly on to a PC. Maximum and minimum values over a period of 24 hours, high and low temperature alarm notification via phone and email were programmed into the system, documented directly and saved as files. We studied one such data logger from Marathon Products, San Leandro CA, the RF2 data logger with its accompanying MDAS-PRO software and adapted this to the IVF laboratory.

Quality Control (QC) in the IVF laboratory plays an important role in the success of any IVF program. The role of QC procedures in the IVF laboratory is to fine tune existing protocols in order to more effectively help infertile patients in their quest to have a healthy baby. The three most important physical conditions in the IVF laboratory that can be controlled are temperature, pH and osmolality. Laboratories are required to document and monitor these physical conditions regularly as part of their ongoing QC/QA programs. Monitoring and documentation of temperatures inside incubators, refrigerators and freezers is an integral part of routine day to day QC in the IVF laboratory and is a prerequisite for accreditation by CAP, JCAHO or other agencies. In laboratories with multiple banks of incubators and freezers this is a time consuming and laborious process. In large volume laboratories this process can take up to 1 hour every day. Here, we find a new application for real time temperature logging by introducing this system into the IVF laboratory. Data loggers continuously transmit temperature of incubator, freezer and refrigerator interiors at set programmed intervals directly on to a PC. Maximum and minimum values over a period of 24 hours, high and low temperature alarm notification via phone and email were programmed into the system, documented directly and saved as files. We studied one such data logger from Marathon Products, San Leandro CA, the RF2 data logger with its accompanying MDAS-PRO software and adapted this to the IVF laboratory.