Covid 19 and the importance of data logging for documenting temperature profiles

Marathon is pleased to announce that the Public Health Department for the State of Alaska in the City of Anchorage has adopted Marathon’s -80° C temperature data loggers for Covid Vaccines.

The Public Health Department in Phoenix Arizona has also received Marathon’s C\TEMP – 80 C data loggers for ensuring dry ice is maintained while delivery and on-site storage of Covid Vaccines. Please consider using any of our cryogenic – 200° C devices for Liquid Nitrogen Applications and our -80° C dry ice data loggers for all vaccine shipments.

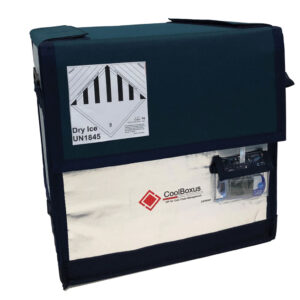

We are pleased to announce our partnership with Hitachi High Tech and their CoolBoxus medical mobile transporters for vaccine, blood and Covid-19 shipments. Marathon’s -200 C NFC enabled data loggers are equipped with each cold box. These will soon be available for widespread distribution in the United States.

“Don’t Ship Without Us!”

Sincerely,

Jon Nakagawa, President

San Leandro, California USA

The COVID-19 Vaccine and Its Impact on Cold Chain

There’s a lot of excitement right now about the development of COVID-19 vaccines and the consequent scale of production to produce millions of them. But, how will these vaccines travel from a medical manufacturer to hospitals and doctor’s offices to be administered to the public? The CDC mandates that vaccines be kept between at least 2°C and 8°C at all times, including during transport. (This temperature range is only acceptable for a maximum of 30 days.)

Thankfully, several cold chain solutions have been used for years to address this very issue within the medical world.

Cold chain solutions that facilitate COVID-19 vaccine distribution

The vaccine cold chain requires specialized equipment and procedures that can verify that a vaccine has been kept at the appropriate temperature from the time it was manufactured, during storage and shipment, right up to the point when it is administered. The chain is so important that any variation in the recommended temperature range can negatively impact the effectiveness of the vaccine. In fact, variations in temperatures as much as one degree above or below the recommended range can render a vaccine ineffective.

Because there is no visual indicator that a vaccine has not been maintained at appropriate temperatures during storage or transport, temperature monitoring devices verify that a vaccine has been handled appropriately. With millions of people worldwide waiting to receive the vaccine, the importance of an effective cold chain system cannot be overemphasized.

Cryo-containers

Cryogenic liquid containers, commonly referred to as cryo-containers, are a key element in the transportation of COVID-19 vaccines. These double-walled vacuum vessels have multiple layers of insulation and are designed to reliably and economically transport and store liquefied gases at cryogenic temperatures.

Taylor Wharton Cryo Express dry shipping containers will safely transport your products at cryogenic temperatures. The temperature inside the shipping cavity remains at approximately -190°C. This is accomplished with liquid nitrogen, and the unit complies with all international road transport regulations.

There are also Taylor Wharton Cryogenic Storage and CBS Cryosystems Storage Solutions. These durable and lightweight containers have a removable lid with a side holder and stainless steel racks with locking rods. Many options are available, including locks and alarms that notify when levels are low.

Liquid nitrogen shipping

One of the most common ways of shipping a vaccine supply is with liquid nitrogen systems. These systems are self-contained and can maintain temperatures as low as –200°C during transport and storage, even over thousands of miles and to distant continents.

There are several options of cryogenic dewars that will store and dispense liquid nitrogen. Wide-mouth and pitcher-style containers along with temperature read-outs make handling your liquid nitrogen supply easy.

Dry ice shipping

Dry ice, the solid form of carbon dioxide, is used for shipping temperature-sensitive products. It is available in blocks or cylindrical pellets and has long been used in cold chain shipping. Because it maintains a cold temperature of – 78.5°C, it is ideal for the storage of products that must remain frozen.

CoolBoxus dry ice shipping containers are a reliable and affordable way to ship COVID-19 vaccines. This reusable product has highly efficient insulation and maintains temperature stability. Available in four sizes, these containers can safely maintain temperatures between -80°C and -60°C for 2-7 days.

Temperature data logging system

Regardless of the delivery system you choose, the most important aspect of your COVID-19 vaccine shipment is the temperature monitoring system. The World Health Organization estimates that almost half of global vaccines are wasted every year due to improper temperature management and data logging.

This means a potential one billion COVID-19 vaccines could be wasted. This is unacceptable anytime, but especially during a global pandemic. The cold chain must be maintained end-to-end, and the best way to ensure this is reliable temperature data logging systems.

Marathon Products, Inc., offers a data-logging system that uses temperature-sensitive probes. When mounted within the shipping container, the probes provide a continuous way to monitor the temperatures of the shipment.

This software-based system provides a visual and recorded account of temperatures along with an audio and visual alert system that activates if the temperatures rise above the recommended range. This system is in great demand as pharmaceutical companies worldwide scramble to distribute millions of vaccines.

For more information on how to improve your cold chain shipping, contact us today.

Article Sources:

https://www.who.int/immunization/programmes_systems/supply_chain/resources/tools/en/ https://www.ups.com/us/en/services/knowledge-center/article.page?kid=art16a454e6661